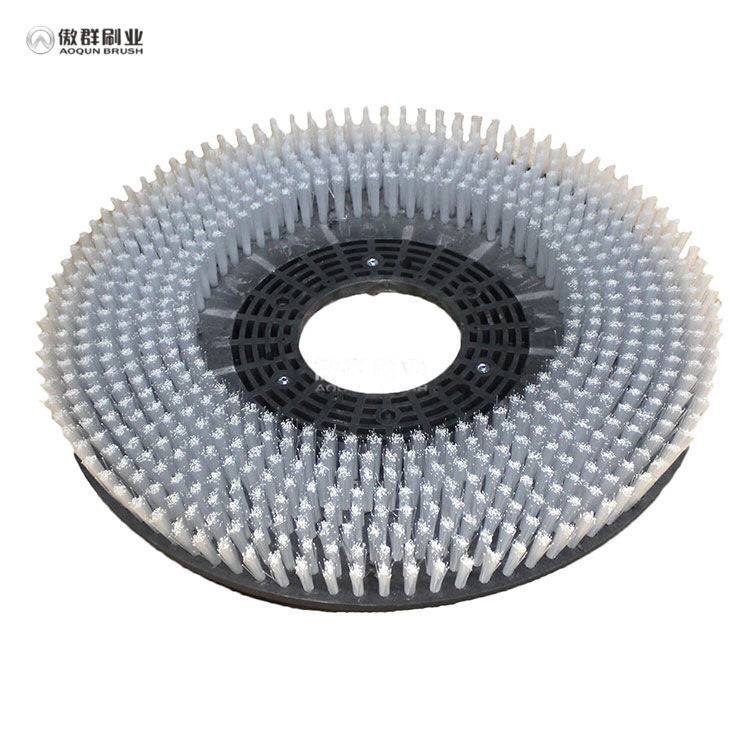

【Multi-function Industrial Brush】Aoqun Disc Abrasive Brush: A Multi-purpose Industry Cleaning and Polishing Innovation

In industrial production, precise surface treatment and efficient production processes are the key to success. Aoqun Technology's disc abrasive brushes are leading the transformation of metal processing, automotive manufacturing and electronics industries with their excellent durability and versatility. Aoqun disc abrasive brush is an advanced tool designed for industrial grinding. It has high durability and a long service life. It can evenly and efficiently polish various complex surfaces, such as hyperboloids, convex surfaces, etc.

The functions of disc abrasive brushes are diverse, and their common functions include:

1. Satin finishing: Use a soft fine polishing brush to perform matte diffuse satin finishing on the surface of the part, giving the surface of the part a non-mirror-like luster;

2. Surface cleaning: Use with a disc polishing brush to clean oxides, rust, old paint layers, welding slag and other stains on the surface of the part, as well as dust remaining after the part is corroded;

3. Thread brushing: By polishing the surface of the part, create fine threads with a sense of design, enhancing the beauty and functionality of the part.

4. Deburring: During the polishing process, remove burrs on the surface and edges of parts to improve the smoothness and safety of parts.

The disc grinding brushes of Aoqun Disc Brush Factory have a wide range of applications, mainly covering the following areas:

1. Metal material processing: Before and after cold rolling, galvanizing, and tinplate material processing, ensure the perfect state of the metal surface;

2. Parts processing: Effectively handle processing burrs and chamfers to improve the overall quality of parts;

3. Compressor parts: Used for the finishing of refrigerator and air-conditioning compressor parts to ensure their efficient operation;

4. Strip surface cleaning: Clean the surface of the winding copper and aluminum strips to ensure the cleanliness and performance of the strips;

5. Circuit Board processing: Clean and grind the copper plate of electronic circuit boards to improve the reliability and performance of circuit boards;

6. Automobile manufacturing: Automobile gear processing, automobile parts deburring, and surface polishing before electroplating and painting;

7. Casting surface treatment: Polish the surface of castings, remove burrs from deep holes and related holes, and improve the surface quality of castings;

8. Furniture processing: Wood grain protrusion processing and convex surface polishing of furniture such as wooden bars and three-boards;

9. Hydraulic parts processing: Grind the cylinder head surface and terminal surface of hydraulic parts to ensure the accuracy and performance of hydraulic parts.

It can be seen that the unique advantages of Aoqun disc grinding brush are as follows:

1. High efficiency and durability

Aoqun disc grinding brush adopts high-strength materials and advanced technology to ensure stability and efficiency in long-term use. Whether it is metal surface cleaning or fine polishing, it can provide consistent high-quality results.

2. Wide application in multiple fields

From metal processing to automobile manufacturing, Aoqun disc grinding brush has demonstrated its strong adaptability in many industries. Whether it is cleaning oxides, removing burrs or fine polishing, this tool can handle it easily.

3. Improve production efficiency and quality

Through precise surface treatment and efficient cleaning, Aoqun disc grinding brushes help companies improve the overall efficiency of production lines, reduce production downtime, and ensure the high quality standards of the final product.

The specific characteristics of each disc grinding brush may vary depending on the model and specifications. In order to obtain more detailed product information or make bulk purchases, it is recommended to contact the disc brush supplier directly to obtain the most accurate product information and professional service support.

сканировать на wechat

сканировать на wechat