The glass front cover is gradually shifting from 2.5D to 3D and 3.5D glass. Especially in the past two years, 3D glass covers have gradually emerged in the market. The material of the back cover of mobile phones has undergone a "plastic-metal-glass" change, and glass has become a mobile phone. Mainstream material. The glass cover polishing brush roller produced by Aoqun has strong adaptability, and it is suitable for the polishing process of 2D, 2.5D, 3D or 3.5D glass cover.

The production of glass needs to go through industrial processes such as original sheet cutting, pretreatment (cutting, edge breaking, edging, drilling, washing and drying), silk screen, tempering, etc. The edging (polishing) link plays an important role, and the finished glass Its brightness is closely related to it. When edging, it is often necessary to use glass polishing brush roller.

When polishing glass, chemical polishing or chemical polishing can be used to remove defects on the glass surface and improve the transparency and refractive index of the glass product. During the polishing process, it is necessary to introduce the polishing liquid or polishing powder into the glass polishing brush roller and the glass surface, and at the same time give a certain pressure to make the glass peeling and polishing brush roller move relative to each other to form fine polishing of the glass surface. The quality of the glass polishing brush roller and polishing powder can often affect the quality of the finished glass. Choosing a low-quality brush roller with uneven brush roller filaments will not only fail to polish, but may also cause optical distortion of the glass.

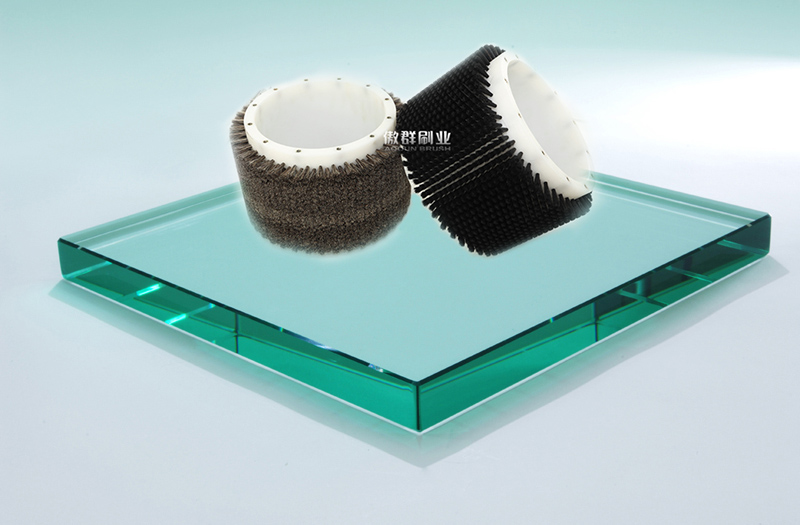

Glass Polishing Brushes

As far as the 3D curved glass cover is concerned, the polishing brush roller occupies a large part of the previous process, and it is a consumable, with a short service life, often only two days.

The glass polishing brush roller produced by Aoqun Mao Brush Factory is made of pure materials, and the special-shaped polishing brush roller can be customized according to the actual polishing needs of the cover plate. The glass polishing brush roller brush roller produced by Aoqun brush roller factory has uniform filaments and is not easy to fall off, has good abrasion resistance, has a straight shape and does not shrink in size. If you need to customize various polishing brush rollers, please contact Aoqun customer service with drawings and samples.

Aoqun Brush Factory provides one-stop brush roller customization service, quick proofing, and provides customers with fast, convenient and caring service. If you need to customize the glass cover polishing brush roller, please contact Aoqun customer service with drawings and samples.

сканировать на wechat

сканировать на wechat